Sustainability ~ Planet

Twin Rivers Technologies Sustainability Program is designed to deliver continuous growth while reducing impact on the global community. We are constantly looking for ways to reduce our operations' impact on the environment. We do this through efforts in energy efficiency, water conservation, responsible sourcing and waste reduction. Monitoring our environmental performance over time allows us to better understand our impacts on the planet and identify opportunities to improve in the future. To find out more information and read the full 2018 Sustainability Report, please click here

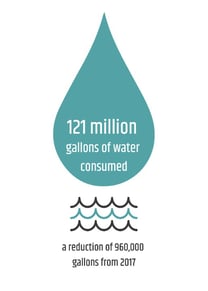

Water Conservation

Water is a critical resource used in our production processes. We continuously explore ways to optimize our production systems to minimize our total water consumption and discharge. Conservation efforts that minimize the amount of water we consume per ton of product produced has been one of our key strategies. TRT’s water conservation efforts have focused on opportunities to replace water supplied from municipal sources with internal sources. TRT has done this through conservation efforts within the production and utilities operations that have included condensate recovery, relocation of storm water discharges, treatment of boiler feed water and use of storm water for noncontact cooling water. Water consumption showed decreases from 2014 to 2016, then an increase in 2017. In 2018 the total amount of water that TRT discharged was over 960,000 gallons of water. It should be noted that discharge volumes are variable and mostly attributable to storm water which is collected onsite and used for process cooling.

TRT’s conservation efforts do much more than save money. They have also led to the reduction of chemicals used for boilers, cooling water treatment, and feed water used to operate both systems. This ultimately reduces treatment required

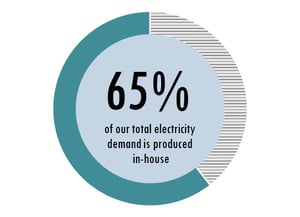

Energy Conservation & Efficiency

Since the addition of natural gas as a fuel option in 2012, TRT’s primary source of fuel is comprised of natural gas but is supplemented by fuel oil and natural oils when the natural gas supply chain is under stress. TRT works with our supplier to utilize other fuels when demand for gas in communities is high.

TRT’s consumption is driven by two main factors: steam production for operations and electric production. Electric production occurs by utilizing the onsite combined heat and power (CHP) plant that was installed in 2014 and came online in 2015. In 2014, production was slightly lower and less natural gas was used. Startup and optimization of the CHP from 2015 to 2016, also lead to downtime reducing CHP utilization. However, in 2017, the CHP plant was almost fully operational, producing its highest amount of electricity. This did require more fuel than in the previous year but secured TRT’s energy supply helping to support sustained operations and energy independence.

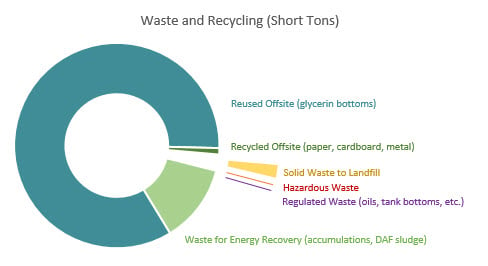

Waste Generation

TRT strives to reduce the volume of its waste streams, which have historically been disposed of to landfills or as hazardous / regulated waste. Through reengineering, reprocessing, energy recovery, recycling or the identification of new sales outlets, TRT has been able to reduce its waste sources that are “disposed of” to a fraction of the total potential volumes.

For more information on our waste reduction program and the other ways in which Twin Rivers Technologies monitors our environmental performance to better understand our impacts on the planet and identify opportunities to improve in the future, please download our 2018 Sustainability Report.